Overview

“Sensor Manufacturing and Process Control” can also be taken for academic credit as ECEA 5343, part of CU Boulder’s Master of Science in Electrical Engineering degree.

This is our fourth course in our specialization on Embedding Sensor and Motors. To get the most out of this course, you should first take our first course entitled “Sensors and Sensor Circuits”, our second course entitled “Motor and Motor Control Circuits”, and our third course entitled “Pressure, Force, Motion, and Humidity Sensors”.

Our first course gives you a tutorial on how to use the hardware and software development kit we have chosen for the lab exercises. Our second and third courses give you three hands-on lab experiments using the kit. This third course assumes that you already know how to use the kit.

You will learn about sensor signal characterization and manufacturing techniques and how to optimize the accuracy of sensors. You will also learn about more advanced sensors, proportional-integral-derivative (PID) control, and how this method is used to give you a closed loop sensor feedback system.

After taking this course, you will be able to:

● Understand how sensor manufacturers characterize and calibrate their sensors.

● Tune a PID control loop and access the PID control function of the Cypress PSoC development kit for a motor control application.

● Understand manufacturing methods used to build electro-mechanical and micro-machined sensors.

You will need to buy the following components to do the two course projects based on the videos in this module. Note that if you have already purchased the PSOC 5LP PROTOTYPING KIT, you do not need to buy it again.

These parts may be purchased off the Digikey web site, www. Digikey.com. Or, you may obtain the specs from the site, and purchase them elsewhere. All are quantity one except for N107-ND where you need three, and 493-15371-ND where you need two.

428-3390-ND

P14355-ND

FQU13N10LTU-ND

N107-ND

1N5393-E3/54GICT-ND

RNF14FTD1K00CT-ND

P0.62W-1BK-ND

493-15371-ND

Additional equipment needed:

• Wire – various gauges and lengths

• Breadboard

• Oscilloscope – suggested models are:

o PICOSCOPE 2204A-D2 available on www.digikey.com or

o Digilent 410-324 | OpenScope MZ available on www.newark.com

Depending on your budget, you can also investigate these models:

o Hantek HT6022BE20MHz – https://www.amazon.com/dp/B009H4AYII

o SainSmart DSO212 – https://www.amazon.com/dp/B074QBQNB7

o PoScope Mega50 USB – https://www.robotshop.com/en/poscope-mega50-usb-mso-oscilloscope.html o ADALM2000 – https://www.digikey.com/en/products/detail/analog-devices-inc./ADALM2000/7019661

Syllabus

Process Control

In module 1 you will learn how companies perform process control in their factories. First, you will review how 2nd order transfer functions work, which is the theoretical basis for much of process control. Then you will learn how plant-wide control systems are implemented and details about the software protocols used to communicate between plant controllers and sensors. Then you will perform a lab for PID control with your PSoC system, which will get you some hands-on experience with this type of control system.

Sensor Characterization

In module 2 you will learn how sensor software is adjusted for optimal performance in the field. First, you will review how non-linear sensor response curves are linearized for more predictable performance. Then you will learn how sensor output is automatically adjusted to account for wide ranges of ambient temperature. Next, you will review how sensors are calibrated, and the certification procedures that companies follow to demonstrate calibration capability. Afterwards, you will study how linearization, compensation, and calibration play into sensor accuracy specs. Finally, you will perform a lab for closed loop motor control with your PSoC system, which will get you some hands-on experience with closed loop systems.

Advanced Sensors

In module 3 you will first learn how radar level transmitters work, and how they are used to provide accurate readings in all types of process tank conditions. Then you will learn about components and design issues for LIDAR systems used in self driving vehicles. Afterwards, we will teach you about how sensors are customized for medical applications. This includes pressure and temperature sensors that are implanted during surgical procedures, as well as pressure and flow sensors used in patient care equipment.

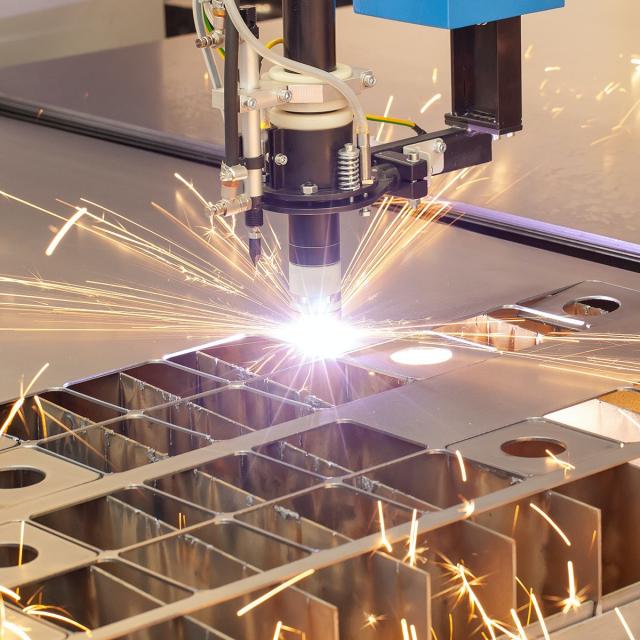

Sensor Manufacturing

In module 4 you will learn how sensors are manufactured. First you will learn how MEMS construction is used to make miniature flow, pressure, and temperature sensors. Afterwards, we will teach you how micro-electronic connections attach the MEMS sensors to connections within plastic encapsulated chips. Then we will discuss how sensor chips are enclosed within sensor housings, and how different designs of housings are used for different applications. Then you will learn how sensors are tested for high reliability in the field.

Course Projects

This module contains the materials you need to complete the PID Control and Closed Loop DC Motor control lab assignments.

Coach

James Zweighaft and Jay Mendelson

Reviews

There are no reviews yet.